1.0 Executive Summary (Final, Fully Upgraded Version)

Zylume is a Slovak sustainable décor brand specializing in the production of affordable, fully biodegradable home décor made from locally sourced natural materials. The company addresses a clear gap within a rapidly expanding market: consumers are increasingly seeking eco-friendly alternatives, yet the affordable décor segment is still dominated by synthetic, plastic-based imports from Asia. Zylume provides a modern, sustainable solution by combining contemporary design, natural materials, and affordable pricing, offering a viable replacement for mass-produced synthetic décor.

1.1 Problem & Opportunity

Seasonal décor is purchased several times per year, the overwhelming majority of products on the market are made from plastics and synthetic composites that take decades to decompose. These items are mass-produced abroad, generating harmful waste as well as high carbon emissions. Although consumer interest in sustainability is growing, the availability of accessible biodegradable décor in Slovakia and Central Europe remains extremely limited almost non existent.

Zylume solves this problem by fully local production while using only natural, compostable materials. The brand eliminates dependence on foreign suppliers, minimizes environmental harm, and brings a modern, sustainable alternative to mass-produced décor.

1.2 Market Potential

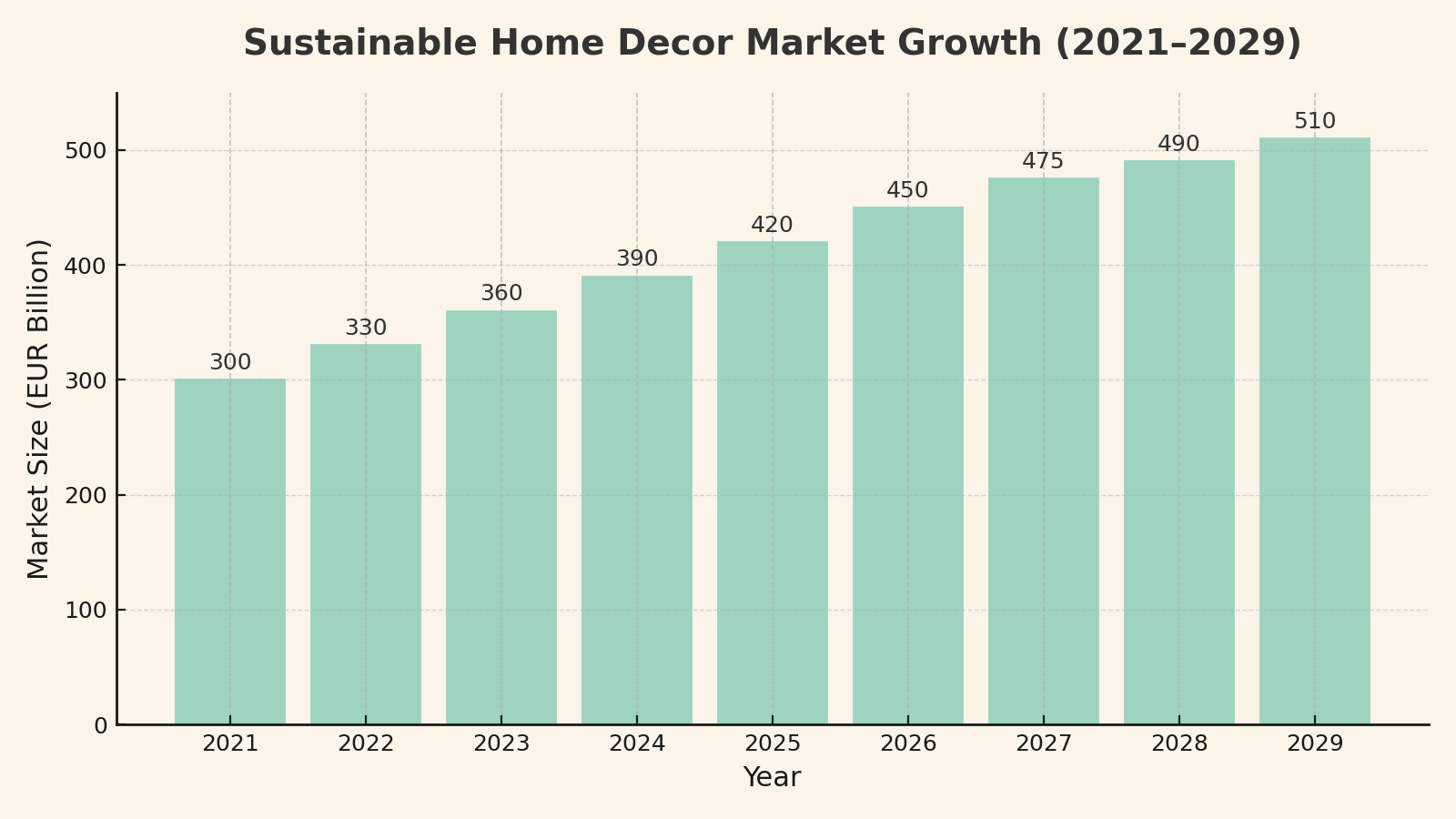

The home décor market in Slovakia exceeds €50 million annually, supported by strong seasonal buying cycles and consistently high customer engagement. Globally, the sustainable décor market is projected to surpass $550 billion by 2031 as consumers shift toward eco-friendly, non-synthetic products. The gap between rising demand and limited supply in Central Europe creates a strategic opportunity for Zylume.

The initial target segment includes urban and suburban households, women aged 25–40, young families, eco-aware consumers, aesthetic-driven shoppers influenced by visual design trends on Instagram, TikTok, and Pinterest and shoppers who are looking forward to decorate their homes each news season with plastic interior decors from abroad.

1.3 Value Proposition & Competitive Advantages

Zylume provides:

- 100% biodegradable décor made from natural Slovak materials

- Fully local production with complete control over design, quality, and supply

- Attractive pricing supported by high margins (70–95%)

- Strong brand identity built around seasonal collections

- A broad product range including vases, wall art, candles, party décor, DIY sets, and more

Zylume is the only brand in the region offering accessible, design-forward décor with full biodegradability and local manufacturing.

1.4 Financial Snapshot

- Funding goal: €70,000 to complete production setup, secure materials, and launch marketing

- Break-even point: 12–16 months after launch

- Year 1 forecast: 15,000 units sold → €45,000 revenue → €25,000–€35,000 net profit

- Average production cost: €0.80 per unit (approx. 73% gross margin)

- Revenue streams: B2C e-commerce selling, and B2B partnerships (schools, municipalities, restaurants)

1.5 Why Now – Timing Advantage

The shift toward sustainable consumption in Europe is accelerating due to new environmental regulations, increased consumer awareness, and a growing rejection of synthetic, mass-produced décor. Affordable biodegradable décor is almost nonexistent in Slovakia and across Central and Eastern Europe, creating a strong first-mover advantage for Zylume.

1.6 Environmental & Social Impact — Revised Version

Zylume reduces waste by offering home décor made exclusively from natural, renewable, and 100% biodegradable materials sourced within Slovakia. The production system eliminates plastics and synthetic additives entirely, lowering environmental impact throughout the product lifecycle. By prioritizing local suppliers and low-energy manufacturing methods, Zylume supports regional economic development while maintaining a minimal carbon footprint.

The company’s approach aligns with EU sustainability objectives and national environmental policies, promoting responsible consumption and circular-economy principles. As a result, Zylume generates measurable benefits in three areas: reducing waste, shifting consumer habits toward eco-friendly products, and creating new local employment opportunities.

CHAPTER 2 — COMPANY DESCRIPTION

Zylume is a Slovak sustainable décor company focused on producing biodegradable, design-forward home décor using natural materials. The company is built on the belief that modern home decoration can be stylish, affordable, and environmentally responsible at the same time. By combining traditional natural materials with contemporary design, Zylume offers an alternative to the mass-produced synthetic décor that dominates the market.

2.1 Mission Statement

Zylume’s mission is to make sustainability part of everyday life by offering home décor that is beautiful, practical, and accessible. Our products are designed to be enjoyed seasonally and then safely composted or disposed of without harming the environment. We aim to demonstrate that modern design does not require plastics, harmful chemicals, or overseas manufacturing. Every Zylume product reflects our core values: natural materials, responsible production, and long-term environmental benefit.

2.2 Industry & Market Positioning

Environmental awareness is rising across Europe, and consumer interest in eco-friendly products continues to grow. In Slovakia, annual spending on home décor and seasonal decorations exceeds €50 million, yet sustainable alternatives remain limited, often expensive, and primarily imported.

Zylume positions itself at the intersection of modern design and environmental responsibility. Unlike large retail chains relying on plastic imports, Zylume produces everything locally, using fully biodegradable materials and zero-waste techniques. Unlike luxury eco brands, we maintain affordable pricing aimed at everyday households.

Our initial customer base consists of urban and suburban Slovak consumers—especially women aged 25–40—who value sustainability, aesthetics, and local products. These customers regularly refresh their homes with seasonal items and are actively seeking natural alternatives to mass-produced décor.

2.3 Company Goals

Short-Term Goals (Year 1 – 2026)

- Establish full production capability for the Autumn/Winter 2026 collection.

- Launch the Zylume e-commerce platform with integrated seasonal releases.

- Begin targeted digital marketing campaigns in Slovakia.

- Start direct-to-consumer sales through the website and social channels.

- Secure at least 10 B2B partnerships with schools, restaurants, municipalities, or event organizers for bulk seasonal orders.

Medium-Term Goals (Years 2–3 – 2027–2028)

- Expand e-commerce sales to five EU regions: Czechia, Poland, Hungary, Austria, and Germany.

- Introduce new categories such as eco-stationery, small furniture accents, and natural textile décor.

- Collaborate with influencers and sustainability-focused creators to strengthen brand visibility.

- Upgrade production using advanced biodegradable materials, including mycelium composites.

- Lease agricultural land through Slovenský Pozemkový Fond to grow selected input plants for decorative materials.

- Open the first small-format Zylume retail shop in Slovakia (dependent on performance and traction).

- Participate in environmental design events and sustainability conferences.

These goals are structured in phases and aligned with achievable scaling. International expansion and physical retail will be pursued only after successfully achieving strong performance in the Slovak market.

2.4 Legal Structure & Compliance

Zylume is currently in its pre-registration phase. After securing funding, the company will be formally registered as a Slovak limited liability company (s.r.o.) in early 2026. This legal structure supports grant eligibility, responsible financial management, and cross-border commerce within the EU.

Zylume will comply with all relevant Slovak and EU regulations concerning product safety, packaging waste, labeling, and environmental standards. Where required, we will obtain certifications or third-party testing, such as fire safety documentation for candles or safety declarations for children’s DIY products. A compliance advisor will be engaged during the initial setup to ensure full regulatory alignment.

2.5 Founding Team

Zylume is led by its founder, Patrik Gaborčík, whose hands-on expertise forms the core foundation of the company. Patrik has spent years experimenting with natural materials, developing biodegradable composites, and designing efficient small-scale production methods. His work includes extensive testing of natural binders, paper and mineral blends, and low-waste manufacturing techniques that allow Zylume to produce durable, fully biodegradable décor at a competitive cost.

In addition to material development, Patrik independently manages product design, prototyping, branding, e-commerce setup, and operational planning. This combination of skills creates a self-sufficient and agile foundation for Zylume. As the company grows, additional roles in výroba, logistika a predaj will be gradually added, but the core vision and innovation remain rooted in the founder’s direct expertise.

2.6 Company Conclusion

Zylume is built on the belief that sustainable living should be beautiful, accessible, and aligned with modern design. By offering biodegradable products at fair prices, we fill the gap between low-cost synthetic imports and overpriced eco décor. With strong consumer demand, scalable production, and a clear position in the Slovak and Central European markets, Zylume is prepared to grow into a leading regional brand for sustainable seasonal home décor.

3.0 Market Analysis

3.1 Industry Overview

Consumer demand for sustainable goods is growing rapidly across Europe. According to the PwC 2024 Voice of the Consumer Survey, over 80% of European shoppers are willing to pay more for products that are environmentally responsible. However, while eco-food and clothing have gained traction, home décor remains dominated by plastic and synthetic imports, especially in Central and Eastern Europe.

The global sustainable home décor market is projected to exceed $550 billion by 2031 (Allied Market Research), driven by climate legislation, green urban development, and shifting values. In Europe, these trends are accelerated by initiatives under the EU Green Deal and the circular economy agenda (CBI Market Trends).

In Slovakia alone, the annual home décor and seasonal decoration market exceeds €50 million. Yet eco-alternatives are still seen as niche, unaffordable, or unavailable. Zylume enters this space with a clear advantage: we offer biodegradable, locally made décor designed to align with seasonal trends at a price point accessible to everyday shoppers.

Figure #1 — Global Sustainable Home Décor Market Growth Projection

3.2 Target Market and demographic profile

Zylume’s primary customers are design-conscious and environmentally aware consumers who value modern aesthetics and natural materials. The strongest demand comes from:

- women aged 25–40,

- urban and suburban households,

- young families establishing or improving living spaces,

- eco-aware consumers across Slovakia and Central Europe,

- aesthetics-driven shoppers influenced by Instagram, Pinterest, and TikTok,

- shoppers who buy home décor from Asian platforms such as AliExpress or Temu.

Slovak Consumer Spending Trends

According to EU consumer data, Slovak households have increased home décor spending every year over the last five years. This growth is driven mainly by women aged 25–40, who are also the demographic most willing to purchase eco-friendly alternatives. This group frequently buys seasonal décor and is highly responsive to new visual trends and biodegradable materials.

3.3 Market Size (TAM / SAM / SOM)

- TAM (Total Addressable Market): ~€50 million (entire Slovak home décor market)

- SAM (Serviceable Available Market – eco décor): ~€12–15 million

- SOM (Serviceable Obtainable Market – achievable share): €80,000–€150,000 in first year

Zylume’s Year 1 revenue projection of €90,000 aligns with the SOM range, making the business model realistic and achievable.

3.4 Consumer Behavior & Buying Motivations

Customer interviews, informal testing, and observed behavior patterns confirm several motivations:

- desire to reduce plastic waste and choose healthier, natural products if they had a chance,

- preference for unique, visually appealing décor,

- regular seasonal purchases (autumn, Halloween, Christmas, Easter, spring, summer),

- high engagement with aesthetic content on social media,

- willingness to pay slightly more for eco products,

- strong preference for brands with authenticity, natural materials, and transparency,

- high interest in eco-friendly, local Slovak brands.

These insights strongly support Zylume’s seasonal, biodegradable, design-focused product strategy.

3.5 Early Market Validation

Zylume conducted early product testing among family members, friends, and individuals from the local community. Although this is not a broad-scale research study, the initial feedback was consistently positive and provided meaningful direction for further development.

Key findings include:

- positive reactions to the modern look and natural texture of products,

- appreciation for décor that is lightweight, natural, and sustainable,

- several testers indicated they would prefer biodegradable décor over plastic items,

- confirmation that Slovakia lacks affordable biodegradable décor options.

These early signals validate the product concept and justify expanding testing through social media and local markets.

3.6 Seasonal Demand Cycles

Seasonality is a major driver in the décor market. The strongest periods include:

- September – November: autumn décor

- October: Halloween

- November – December: Christmas

- March – April: spring and Easter

- June – August: summer and outdoor décor

Zylume’s seasonal product model is directly aligned with these recurring cycles, enabling predictable sales peaks and repeat purchases.

3.7 Market Conclusion

Both Slovak and Central European markets show a clear, measurable opportunity for biodegradable home décor. While consumer demand for natural and sustainable products is increasing, the supply of affordable eco-friendly décor remains extremely limited. With its local manufacturing, modern design, competitive pricing, and sustainable materials, Zylume is ideally positioned to fill this gap and build a strong presence in the region.

4.0 Product Line, Services and Materials

Zylume offers a variety of seasonal home decor, party items, DIY kits, and lifestyle products, all made using biodegradable materials, items are made the way it used to be done before the appearance of synthetic materials. In the past people made products from what they got from the nature. We are sort of turning back to this way of making items by choice. Each product is developed through in-house experimentation with different non-synthetic materials, whike maintaining style and price control, without relying on third-party manufacturers or synthetic components.

Below is an overview of our key product categories. For a detailed breakdown where each category is explained thoroughly, see Chapter 12 – Appendix B: Product Manufacturing and Design Details.

4.1 Product Line :

Table #1 of products materials and use :

| Item | Materials used | Use & everyday decor |

| Vase | Plaster, paper pulp, hemp, flour | Seasonal & everyday decor |

| Paintings, canvases | Cotton canvas, wood, casein ink | Wall decoration, gifting |

| Candle holders | Geopolymer,plaster, perlite, hemp, paper pulp | Tabletop & shelf decor |

| Lamps | Plaster, paper pulp, hemp, flour | lighting decor |

| Candles | Soy/beeswax, geopolymer jar | Home fragrance, ambiance |

| Wood table decor | Pressed pulp,flour, casein, chalk powder, thin wood sheets | Event & table styling |

| Wall Clocks | Wood dust, perlite, casein glue, paper pulp | Functional wall decor |

| Door banners | Paper pulp,flour, wood sheets | Door/table seasonal decor |

| Banners | Cotton paper, jute, bioplastic | Event, celebration styling |

| Frames | Pressed paper pulp, casein | Statement wall art |

| Cosmetics (Bath Bombs, Disinfectants, Natural Foam some outsourced) |

Natural oils,Starch, Citric acid | Personal care, gifting |

| Branch wreaths | Branches, cotton ribbons, | Door seasonal decor |

| Party accessories (Piñatas,

Garlands, Confetti, Hats, Tableware) |

Plaster, paper pulp, hemp, flour | Parties & celebrations |

| Home Kraft | Paper pulp, wood,casein paint | Crafting, kids activities |

4.2 Seasonal Products

Besides the main categories mentioned above, we will include seasonal themed items for specific seasons such as autumn, spring and winter.

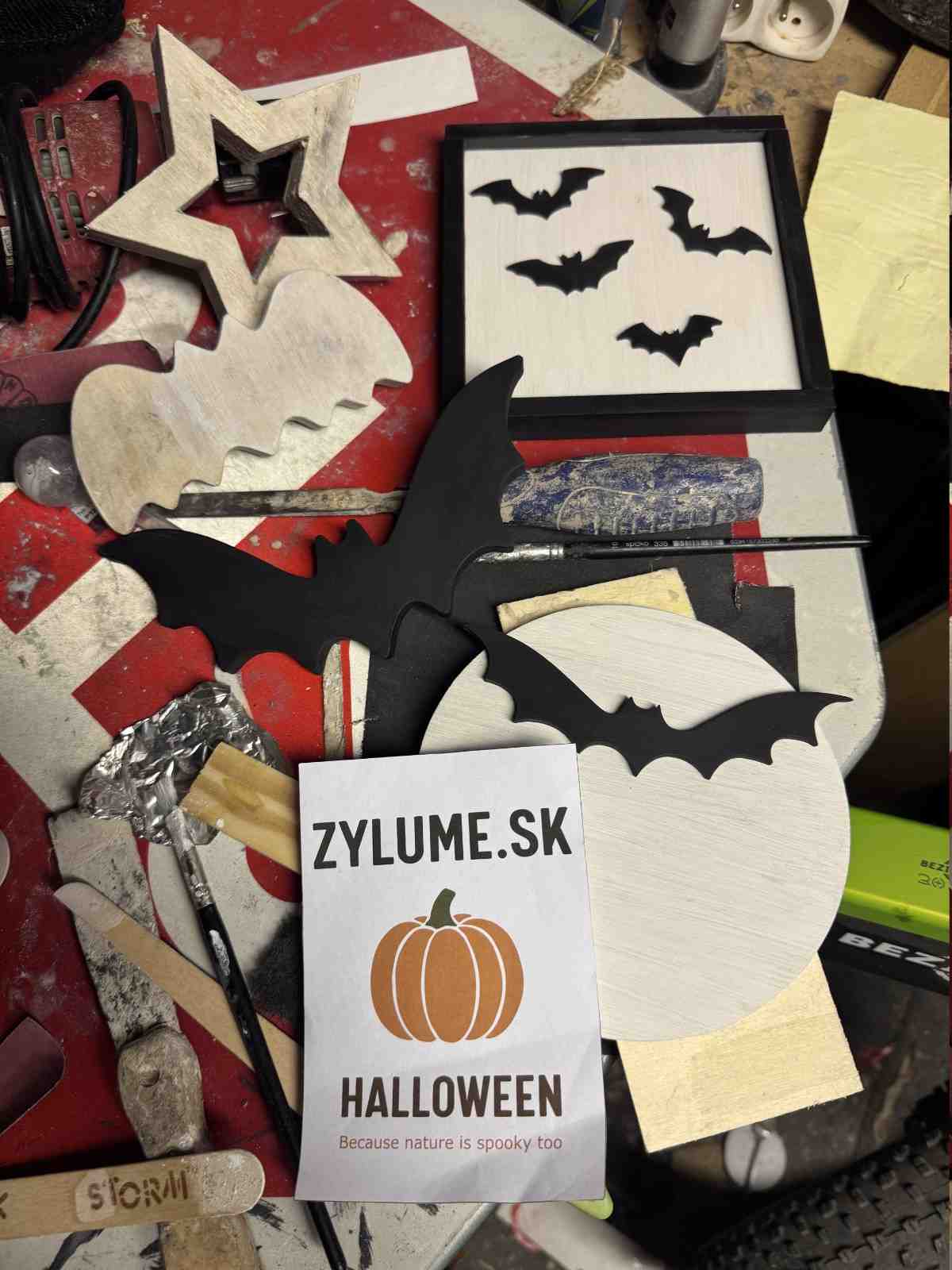

Autumn (Halloween):

- Paper mache pumpkin (also in offer for in bulk)

- Wall vampire bats decor

- Various creatures (spiders, birds, black cats)

- Spooky wreaths

Spring (Easter):

- Decorative creatures such as rabbits, chicks

- Easter eggs to color

Winter (Christmas):

- Christmas bulbs

- Holiday wreaths

- Hanging ornaments

- Christmas themed candles

- Holiday mask kits

4.3 Future Product Development

As Zylume grows, we will expand our product offerings through innovation.

- Textile and clothes – all natural textile (cotton, linen)

- Items made from specific bio materials such as mushrooms mycelium (packaging, vases)

- Furniture

- Ceramics – utilized for producing durable and functional home items, including cups, bowls, and other tableware

4.4 Outsourced products

Some products that need longer production times or require special machinery will be outsourced . These include items such as notebooks, pencils, paper napkins, wooden cutlery, and eco gift packaging. In the future, once we have a strong position in the market, we may start producing some of these outsourced products ourselves.

4.5 Estimation of Cost and Profit per Product

The table below provides estimated production costs and profit margins for each item. These figures are indicative and may be adjusted over time as pricing evolves. All values are shown excluding VAT.

Please note that production cost estimates do not include labor, electricity, or mold-related expenses. However, the production process is fully standardized — employees follow clearly defined steps, ensuring a streamlined and efficient workflow with no need for improvisation.There is a chapter about the electricity costs per month with detailed explanation

Energy consumption is minimal, and we plan to offset it by installing solar panels through available sustainability grants, ensuring clean, low-cost, and market-independent energy. Mold costs remain low due to our system of reusing and recycling molds across production batches.

Table #2 Production cost and profit per item on average

| Item | Production cost € | Selling € | Profit € | Margin % | Note |

|---|---|---|---|---|---|

| Vase | 0.3 | 6 | 5.7 | 95% | |

| Painting | 1.2 | 6 | 4.8 | 80% | |

| Frame | 1 | 3 | 2 | 66.67% | |

| Candle holder | 0.35 | 4.65 | 4.65 | 93% | |

| Candles | 0.6 | 1 | 0.4 | 40% | |

| Wood table decor | 0.3 | 5 | 4.7 | 94% | |

| Wood wreath | 0.3 | 5 | 4.7 | 94% | |

| Wall clock | 1 | 5 | 4.9 | 80% | |

| Paper garland | 0.1 | 3 | 2.9 | 96.67% | |

| Party hats | 0.1 | 5 | 4.9 | 98% | |

| Mask to color | 0.1 | 3 | 2.9 | 96.67% | |

| Mache animals | 0.1 | 5 | 4.9 | 98% | |

| Signage | 0.1 | 5 | 4.9 | 98% | |

| Confetti (one tube) | 0.1 | 1 | 0.9 | 90% |

4.6 Production Timeline

We want to start with the production as soon as the workshop is ready, by the beginning of March, if all goes well so we can start with the manufacturing.

4.7 Shipping & Logistics

Zylume will utilize a combination of trusted shipping providers to ensure reliable and cost-effective delivery of our products across Slovakia and neighboring EU countries. We will primarily work with GLS, DPD, and Packeta (Zásielkovňa) — three of the most widely used logistics services in the region.

- GLS & DPD — Used for standard home deliveries and larger or bulkier shipments. The average business shipping rate for standard parcels ranges from approximately €4.50 to €7.50, depending on size and destination within Slovakia. As parcel volume grows, shipping rates are expected to decrease.

- Packeta — Preferred option for smaller items and flexible pickup. Customers can collect their orders from local pickup points across Slovakia and abroad. The average business shipping rate with Packeta is between €2.70 and €4.50 per parcel.

As order volumes grow, we will monitor delivery costs, customer satisfaction, and shipping performance. Shipping costs will be included in the total order amount of a purchese, and all orders over €35 will qualify for free shipping.

4.8 Conclusion – Product Line, Services and Materials

Zylume’s product line is built on minimazing costs and maximizing profit by having total control over the production. Every item — from vases and wall art to party decor and personal care — has been carefully designed to be aligned with our philosophy and mission.

As we grow, our offerings will expand with new seasonal collections and entirely new categories, including stationery, textiles, and eco-friendly furniture. With standardized production, low mold costs, and minimal energy use, Zylume is positioned to scale efficiently while offering products that reflect the values of modern, conscious consumers.

5.0 Competitive Analysis

5.1 Market Positioning

The home décor market is diverse, ranging from mass-produced synthetic products sold by large retailers to expensive handcrafted pieces offered by specialty brands. Within this landscape, Zylume is in the middle, offering stylish, biodegradable, and modular décor at prices that remain accessible.

5.2 Competitor Overview

The following section shows the main competitive players and how Zylume differentiates itself

Figure #2 — Competitive Landscape: Brands & Positioning

We compare our offering on three key dimensions:

- Price vs. quality — Many cheap brands use non-eco materials, We use natural materials while still keeping our prices low.

- Sustainability vs. mass-production — Most products are made in big factories. We focus on local production.

- Design & seasonal updates — Many décor brands offer limited and boring designs, so people quickly lose interest. We create new collections every season and between seasons, giving customers something fresh to look forward to all the time.

5.3 Competitor Benchmark Table

Below is a summary of the main competitors and how Zylume differentiates itself:

Table #3 table of competitors

| Shop name | Price | Materials | Style | Local production |

|---|---|---|---|---|

| TEDi | Cheap | Synthetic | Simple/Basic | x |

| Sinsay | Cheap | Synthetic | Scandinavian / Modern | x |

| Pepco | Cheap | Synthetic | Simple/Basic | x |

| Flying Tiger | Cheap | Synthetic | Playful | x |

| Sashe | Expensive | Natural, mixed | High end decor | Yes |

| Etsy | Medium expensive | Natural, mixed | Mainly home crafted | Yes |

| Hobbycraft | Medium, expensive | Mixed | Crafty, artificial | No |

5.4 Conclusion

In summary, while the market includes large established décor brands and smaller eco-focused players, Zylume offers a unique position by combining affordable pricing, fully biodegradable materials, and visually appealing design.

6.0 Marketing & Sales Strategy

6.1 Sales Strategy

Zylume’s revenue will come from two key sources: direct consumer sales (B2C) and business partnerships (B2B).

B2C – Direct-to-Consumer Sales

Zylume’s B2C strategy focuses on everyday consumers by selling the products on:

-

Online via Zylume.sk

Our official online store will be the main platform for browsing and buying products. Fully fully optimised for both desktop and mobile devices (a demo version is already live).

B2B – Institutional & Bulk Sales

The company's B2B strategy focuses on selling items in bulk to companies, organizations, and city councils. These partners can use our products to decorate offices, stores, schools, or public spaces for specific events or upcoming seasons — just like individual consumers do. Our main B2B customer groups include:

- Schools & Educational Institutions — Bulk DIY kits and seasonal craft materials that support creativity and environmental education in classrooms.

- Event Planners & Wedding Organizers — Partnerships for eco-friendly events using compostable decorations and natural signage.

- Retailers & Boutiques — Bulk supply of décor items for shops and companies that want to create inviting, nature-inspired spaces.

- Public Institutions & Local Councils — Branded seasonal décor for municipal events, community centers, and cultural festivals.

6.2 Marketing Strategy

Over the past year, we have developed a marketing strategy that combines visual storytelling, guerrilla campaigns, and community-based actions to attract attention and build interest in the brand. This strategy clearly highlights that our products are made from natural materials and remain affordable for everyday consumers.

We will focus on both traditional and digital marketing. This includes printed flyers and local promotions to reach nearby communities, while also building a strong presence on social media to connect with a wider audience. By combining these marketing strategies, our goal is to create a strong and lasting connection between customers and the Zylume brand.

6.3 Direct & Physical Marketing

Leaflet Campaigns

We will produce our own brochures, using stamping or screen printing on the cover to highlight our brand. The inside pages will be printed with commercial water-soluble ink, allowing us to show clear visual images. The paper used will be outsourced, so we can print and distribute a larger number of flyers efficiently. These brochures will be shared widely to increase local visibility and brand awareness. leaflets will be our most efficient way of marketing our business mainly because people are tired of all the adds on social media.

Farmers’ Markets & Seasonal Events

Participation in farmers’ markets in two of the biggest Slovak cities (Bratislava and Košice) will give customers their first opportunity to see and touch our products in person. We will set up an attractive stand that showcases our collections in a creative and eye-catching way, helping us stand out from other vendors. These events will also allow us to present new collections, build local partnerships, and strengthen brand visibility.

Conference Speaking & Target Events

Zylume will speak at selected conferences to share our story: why the brand was founded, how we create biodegradable décor, and how our products contribute to environmental responsibility. We will focus on events related to sustainability, design, manufacturing, and responsible business practices.

At these events we will:

- Share our journey from idea to finished product

- Explain how we use eco-materials and circular manufacturing methods

- Highlight what makes our brand different from conventional décor producers

- Connect with partners, customers, and investors

Target conferences and events include:

- AmCham ESG Conference – Bratislava

- Decarbonising Slovakia’s Economy – National green transition conference

- XXIX International Scientific Conference: Engineering for Environmental Protection – Rajecké Teplice

- IALE 2025 European Landscape Ecology Congress – Bratislava

- Czech & Slovak Sustainability Summit 2025 – Prague

These platforms allow Zylume to present its production model, material innovation, and long-term vision to professional audiences involved in environmental policy, design, business development, and green investment.

Conference appearances will also serve as a marketing tool. We will transform our speaking engagements into blog content, social media posts, and digital coverage. These activities increase our chances of being noticed by journalists and media outlets, allowing our story and mission to reach a wider audience. Conference speaking will therefore strengthen brand visibility and position Zylume as a credible voice in sustainable design.

6.4 PR & Media Outreach

Public Relations & Media Strategy

We will also look for and use media and journalists to write about Zylume. Instead of paying only for ads, we will tell our story directly to newspapers, blogs, and online platforms. If they find it interesting, they will write about us, how we work, and what makes our products special. This helps more people discover Zylume in a natural and trusted way.

6.5 Marketing Timeline – Key Activities for 2026 Launch (Winter Season)

Pre-Launch Plan

- Set up social media platforms (Instagram, Facebook, Pinterest, Snapchat) – done.

- Run paid ad campaigns targeting early interest and email sign-ups before sales begin.

- Distribute eco-themed leaflets in cities like Bratislava, Košice, Trnava, Žilina, and Prešov.

- Attend eco fairs and community events to showcase products face-to-face.

- Capture and share event content (behind-the-scenes videos, reactions, brand story).

- Launch a pre-order campaign with early-bird perks (free ornament, seed paper, discount).

6.6 Chapter Summary – Marketing & Sales Strategy

Zylume’s marketing focuses on creative ideas, community actions, and simple digital promotion to help people notice the brand and connect with it. We will sell our products in two ways: directly to customers through our website, social media, and events, and also to businesses like schools and event organisers.

Our marketing will include eco leaflets, seasonal catalogues, clean-up events, and other creative activities to build trust and get people talking about the brand. Online, we will use simple ads, social media, and useful content to stay connected with our audience.

We will focus strongly on promoting Zylume before the autumn season of 2026, so people are already aware of the brand and ready to buy when sales begin.

7.0 Financial Plan, Projections & costs

This chapter provides a clear forecast of Zylume’s financial performance for the next three years. It outlines expected revenue, production costs, operating expenses, and profit margins based on realistic assumptions. The projections show how much investment is needed and it will be used, when the company will reach break-even, and how the business will grow as production increases. The goal is to demonstrate that Zylume is financially viable, scalable, and capable of generating stable long-term profits.

7.1 Use of Funds & Startup Costs

We are seeking a minimum of €100,000 in funding to fully launch and scale Zylume. This capital will cover all essential startup needs — from equipment and materials to workspace setup and marketing to make sure we are ready to launch the production by March of 2026 and e-commerce sales by August 2026. While our target is €100,000, we are flexible and open to discussing different funding arrangements to suit investor preferences.

The funds will be used for the following needs:

-

Workshop Setup & Equipment

- Purchase essential tools and machinery for material processing and mold production.

- Renovate and equip the workspace (drying room, lighting, ventilation, workstations).

-

Materials & Production Readiness

- Purchase core raw materials (wood, biodegradable binders, sand, plaster, casein).

-

Operational Support

- Hire part-time staff for production, packaging, and seasonal workload.

-

Branding & Digital Infrastructure

- Finalize and optimize the e-commerce store (Zylume.sk).

- Pay for digital ads on social media platforms.

-

Marketing & Launch Campaigns

- Create digital content and run targeted ads for the Halloween 2026 campaign.

- Produce seasonal promotional materials, including eco catalogues and social media assets.

-

Transportation & Logistics

- Purchase a utility vehicle to transport materials, products, and equipment between the workshop, suppliers, and local markets.

7.2 Table of the Costs

The table below provides a detailed cost breakdown of the essential resources needed to start manufacturing operations. A complete list of the items to be purchased can be found in Appendix B.

Table #4 — Startup Cost Breakdown

| Expense Type | Amount € |

|---|---|

| Equipment & Machinery | 19,698.52 |

| Workshop Renovation (Materials) | 5,090.75 |

| Workshop Renovation (Labour) | 10,400.00 |

| Initial Manufacturing Materials | 5,000.00 |

| Utilities (Electricity & Water – Year 1) | 1,750.00 |

| Marketing (Year 1) | 2,550 – 3,000 |

| Administrative & Compliance | 2,000.00 |

| Seasonal Labour | 1,200.00 |

| Reserve & Contingency Fund | 10,000.00 |

| TOTAL STARTUP COST | 57,689.27 – 58,139.27 |

Total amount approximately needed: around €100,666.11.

Figure #4 — Zylume Startup Funding & Cost Overview

7.3 Break-Even and Profit Timeline

Zylume aims to be fully operational by March 2026, with products ready for sale ahead of the autumn (Halloween) season by July 2026. Once production begins, we expect to cover all monthly operating costs by the end of 2026, following the winter season, and to achieve stable profitability from that point forward.

This projection is based on a realistic setup timeline, controlled operating costs, and strong market positioning.

Our confidence is supported by key factors:

- Seasonal demand peaks during autumn and winter, when spending on home décor is highest. Zylume will focus on these high-impact periods to maximise revenue and profitability. (Source: Capital One Shopping – Halloween Spending Stats)

7.4 Sales Estimation (First 3 Months: September – December 2026)

During the first sales period (September–December 2026), we realistically project sales of approximately 10,000 units.

The average retail price per item is estimated at €3.50, resulting in total revenue of approximately €35,000 (excluding VAT and taxes).

With in-house production and low material costs, the estimated production cost per unit is €0.50, bringing total production costs to approximately €5,000. This results in an estimated gross profit of €30,000 (pre-tax).

Operating expenses will be covered by the initial investment. A portion of the profit will be reinvested into the business to support expansion and the development of future seasonal collections.

7.5 Conclusion – Financial Plan & Projections

Zylume is a lean business with low operating costs, strong margins, and high seasonal demand. With €100,000 in funding, we will start full in-house production, launch our first collections, and begin selling before the Autumn season in August 2026.

In our first year, we expect to sell around 10,000 products, creating approximately €35,000 in revenue and around €30,000 in gross profit (before tax). With good cost control and growing interest in sustainable décor, we expect to break even by the end of 2026 and continue growing from there.

8.0 Risk Assessment & Mitigation

At Zylume, we try to stay one step ahead of problems. We regularly check our work and the market so we can spot risks early and deal with them before they become serious. Below, we describe the main problems that could happen and the practical solutions we have prepared to keep the business running smoothly.

1. Seasonal Cash Flow Fluctuations

Risk: Sales are not continuous throughout the year, because home décor is not a daily-need product like food.

Mitigation: Our business is built to make the most profit during each main season. Every seasonal campaign (Christmas, Halloween, Easter, etc.) will be planned to earn strong profits. The focus on strong seasonal periods is part of our strategy, not a weakness.

2. Founder Overload / Labor Management

Risk: Too much dependence on the founder could limit growth and reduce efficiency.

Mitigation: All production and admin processes are clearly organised and written down. Seasonal part-time workers will take care of making the products, packaging, and logistics. The founder will oversee quality control and administration. As sales grow, dedicated staff will be hired to support daily operations and reduce pressure on the founder.

3. Scaling and Production Efficiency

Risk: Moving from small-batch production to larger-scale manufacturing may cause delays or changes in quality.

Mitigation: The production process is designed as a clear, repeatable system. It does not rely on one person’s “handmade” style. Every stage follows a step-by-step guide, which makes it easier to keep the same quality and scale up production when demand increases.

4. Marketing Costs vs. Returns

Risk: Marketing expenses could become a heavy financial burden.

Mitigation: Zylume keeps external costs low by producing its own flyers, brochures, and promotional materials. Each leaflet costs only about €0.10 to make — so 1,000 high-quality brochures can be produced for around €100. Marketing expenses are expected to stay within 5% of the total budget. Thanks to modern tools, low-cost, good-quality video content is also realistic and fully achievable.

5. Material Availability and Cost

Risk: Problems with the supply of biodegradable materials could slow production or increase costs.

Mitigation: Our main materials — such as micellar casein, plaster, hemp fiber, and wood — are widely available in Slovakia and are not tied to a single supplier or region. Casein, for example, is commonly sold as a fitness supplement, which supports stable supply and pricing.

6. Low Initial Brand Awareness

Risk: Launching a new brand in a competitive market may result in slow early customer interest.

Mitigation: Zylume stands out through authenticity and a clear purpose. We are not competing with mass-market plastic décor, but offer aesthetic, sustainable, and affordable alternatives. Our story-driven marketing, local presence, and eco positioning are designed to attract attention and build loyalty over time, similar to brands such as Lush, Patagonia, IKEA, Method, and Who Gives a Crap.

7. Consumer Price Sensitivity

Risk: Some customers may choose cheaper synthetic décor instead of eco-friendly products.

Mitigation: Zylume’s prices are competitive with platforms like Temu, AliExpress, and Shein, but our products offer more than just low cost. They provide a real artistic and sustainable experience. We offer style, quality, and a clear conscience — not only savings.

8. Overstock and Unsold Seasonal Products

Risk: Leftover products after a season could block cash flow or take up storage space.

Mitigation: Zylume’s products are reusable and can be refreshed or repurposed for future collections. Leftover materials can be reprocessed into new items, supporting a near zero-waste production cycle and reducing financial pressure from unsold stock.

9. Drying Conditions & Climate Influence

Risk: Weather and humidity could slow down or interrupt the drying process of natural materials.

Mitigation: A dedicated drying unit will be installed in the production facility to keep drying conditions stable all year. During warmer months (April–August), open-air drying will also be used to reduce energy costs while keeping production efficient.

10. Certification & Eco-Labelling Requirements

Risk: Future regulations may require certifications or eco-labels for sustainable products.

Mitigation: Zylume’s trust does not rely only on external labels. We focus on transparency and education. Our process will be shown openly through videos, product breakdowns, and direct communication with customers. This allows people to see how items are made, understand the materials, and build real trust in the brand.

11. Growth of AI Companies

Risk: The fast growth of AI may make some investors question why they should support a physical manufacturing business instead of an AI startup.

Counter Argument: AI is growing quickly, but as long as people are human, they will still want real, physical experiences and objects. In an AI-driven world, many people will value companies like Zylume even more, because we offer something they can actually touch, feel, and use in their homes.

A good example is the book industry. Even though digital reading is popular, many people still prefer holding a real book. Physical book sales remain strong, which shows that authenticity and human connection never go out of style.

Another important point: many small AI startups have already been overtaken by the platforms they depend on. For example, many “wrapper” startups built around ChatGPT were no longer needed once OpenAI added those same features directly into ChatGPT.

This shows that AI-based startups can have short lifespans and strong dependency on big platforms. In contrast, physical manufacturing like Zylume creates long-term, independent value through tangible products, a strong brand, and direct trust with customers.

8.2 Conclusion – Financial Plan & Projections

Every business faces problems. What matters is how quickly and effectively those problems are solved. At Zylume, we see challenges as chances to improve, adapt, and grow stronger. By staying flexible, creative, and focused on solutions, we can turn setbacks into progress and keep moving toward our long-term goals with confidence.

9.0 Organization & Management

9.1 Current Structure

Zylume is currently operated by its founder, Patrik Gaborčík, who manages all areas of the business — including product design, material development, production, branding, and daily operations. With over five years of experience in corporate environments such as AT&T, IBM, and Kyndryl, and currently working at Holcim, Patrik brings strong skills in process management, innovation, and strategic thinking. Once funding is secured, the founder will resign from his current position and fully dedicate himself to running. Patrik is fluen in 5 languages ( Slovak, Hungarian, English, French, Polish) Zylume on a full-time basis.

In addition to his operational background, Patrik the founder has dedicated significant time to researching and refining natural material mixtures to achieve the desired balance of biodegradability, strength, and aesthetic appeal. Through continuous testing and experimentation, he developed proprietary formulas that align with Zylume’s sustainability mission, ensuring every product is both environmentally responsible and suitable for daily use.

Patrik is currently responsible for:

- Product development and material research

- Manufacturing and quality control

- Marketing direction and branding

- E-commerce setup and customer experience

- Business strategy and long-term growth planning

His multidisciplinary approach ensures consistency, innovation, and deep knowledge of every product and process within the company.

9.2 Future Hiring Plans

As the sole founder, Patrik has independently planned Zylume’s production, sales, and marketing strategies for launch. At the same time, collaboration with marketing professionals, designers, and sustainability experts is welcome to help expand the brand’s reach and overall impact.

To meet seasonal demand, temporary workers will be hired to support production in the lead-up to each collection launch. These part-time team members will assist with packaging, assembly, and logistics to ensure timely seasonal rollouts.

9.3 Team & Operational Structure (Year 1)

Leadership & Core Operations

All marketing, content creation, sales, and leadership responsibilities will initially be managed directly by the founder to maintain creative consistency and protect the brand’s core vision. As the company grows, fewer areas will be handled by the founder, and responsibilities will gradually be transferred to dedicated professionals in each field.

Future Roles

As Zylume scales and production volume increases, new roles will be introduced to maintain operational quality and accelerate growth. Planned future positions include:

- Production Specialist – To optimize and scale manufacturing systems and material development.

- Marketing & Content Manager – To manage digital storytelling, campaigns, and community growth.

- Sales & Partnerships Lead – To expand wholesale and B2B opportunities with retailers and institutions.

9.4 Conclusion

Zylume’s operations are currently led by the founder to ensure strong quality control and a clear, unified vision during the early startup phase. As the company grows, strategic hiring and collaborations will be introduced to improve efficiency, support scalability, and encourage innovation. This gradual approach helps Zylume stay lean, flexible, and closely aligned with its sustainability mission.

10.0 Additional Information on the Business Model & Future Strategies

At Zylume, sustainability is not just a marketing term — it is the foundation of our business. We create décor in an eco-friendly way, but we do this with a clear goal: to build a profitable company. By offering sustainable and visually appealing products to attract the customers.

10.1 Material Integrity & End-of-Life Design

We start creating every product by asking one simple question: “What happens to this item after it is thrown away?” While many décor brands use plastics, synthetic glues, and petroleum-based materials but still call themselves eco-friendly, Zylume is committed to using only 100% natural materials. This is one of our key messages to customers and a central part of what makes our brand different.

All materials are developed in-house using blends of:

- Recycled paper and cotton pulp

- Volcanic ash and sand

- Cornstarch and plant-based binders

- Rosin and linseed oil finishes

- Casein-based or Arabic gum inks

- Jute, wool felt, and natural waxes

- Dried plants

This ensures that every Zylume product — from vases to banners — breaks down naturally and safely, leaving no toxic waste behind.

10.2 Zero-Waste Production Model

Zylume follows a simple, low-impact production system:

- In-house manufacturing reduces emissions from transport and outsourcing.

- Material waste is reused — paper, dust, or powder scraps are recycled or composted.

- Water usage is kept low, and harsh chemicals are not used.

- Packaging is 100% compostable, made from recycled kraft material and water-based glue.

This local and efficient model reduces our environmental footprint and also lowers costs, helping us keep our products affordable without compromising our values.

10.3 Community Impact & Regenerative Action

For Zylume, sustainability goes beyond materials. It also includes positive impact on the local community and nature. We want to actively involve people in meaningful environmental actions.

Eco initiatives include:

- Clean-Up Events – Organising community clean-ups in parks, riversides, and public spaces.

- Tree & Flower Planting – Seasonal planting activities with schools, volunteers, and youth groups.

- Educational Workshops – Zero-waste and creative workshops for families, children, and local communities.

These activities raise awareness, build stronger community ties, and create real environmental impact while strengthening Zylume’s brand image.

10.4 Reusability, Seasonality & Minimalism

Zylume products follow natural seasons — spring, summer, autumn, and winter. Each item is designed for reuse or short lifecycle use, allowing customers to refresh their décor without guilt or unnecessary waste.

10.5 Future Goals

As Zylume grows, we will continue to improve our sustainability approach. Our future goals include:

- Using solar-assisted and low-energy production equipment.

- Printing with natural dye inks, including sugar-based edible inks.

- Partnering with NGOs and educators to promote environmental awareness and strengthen brand impact.

10.6 Agricultural Integration & Land Use

A long-term goal of Zylume is to connect farming with production. We plan to lease or purchase unused land from the Slovak Land Fund to grow plants that support our seasonal product lines.

Planned crops include:

- Pumpkins – For Halloween décor and autumn sales.

- Luffa (Loofah) – For cosmetic and bath products.

- Decorative Plants – For biodegradable wreaths and ornaments.

- Fast-Growing Trees – For long-term material and ecological use.

This approach supports biodiversity, lowers raw material costs, and helps regenerate unused land. Zylume will work with agricultural experts to ensure all activities meet EU environmental standards.

Note: The founder, Patrik, has already planted fast-growing trees on an SPF-managed plot for personal sustainable use, demonstrating real commitment to this model.

10.7 Conclusion – Sustainability & Impact Strategy

Zylume is not only a product company — it represents a new way of thinking about our relationship with nature. In a market full of greenwashing, we focus on honesty, transparency, and real environmental value.

At Zylume, sustainability is not just a feature — it is the business model.

11.0 Milestones & Growth Timeline

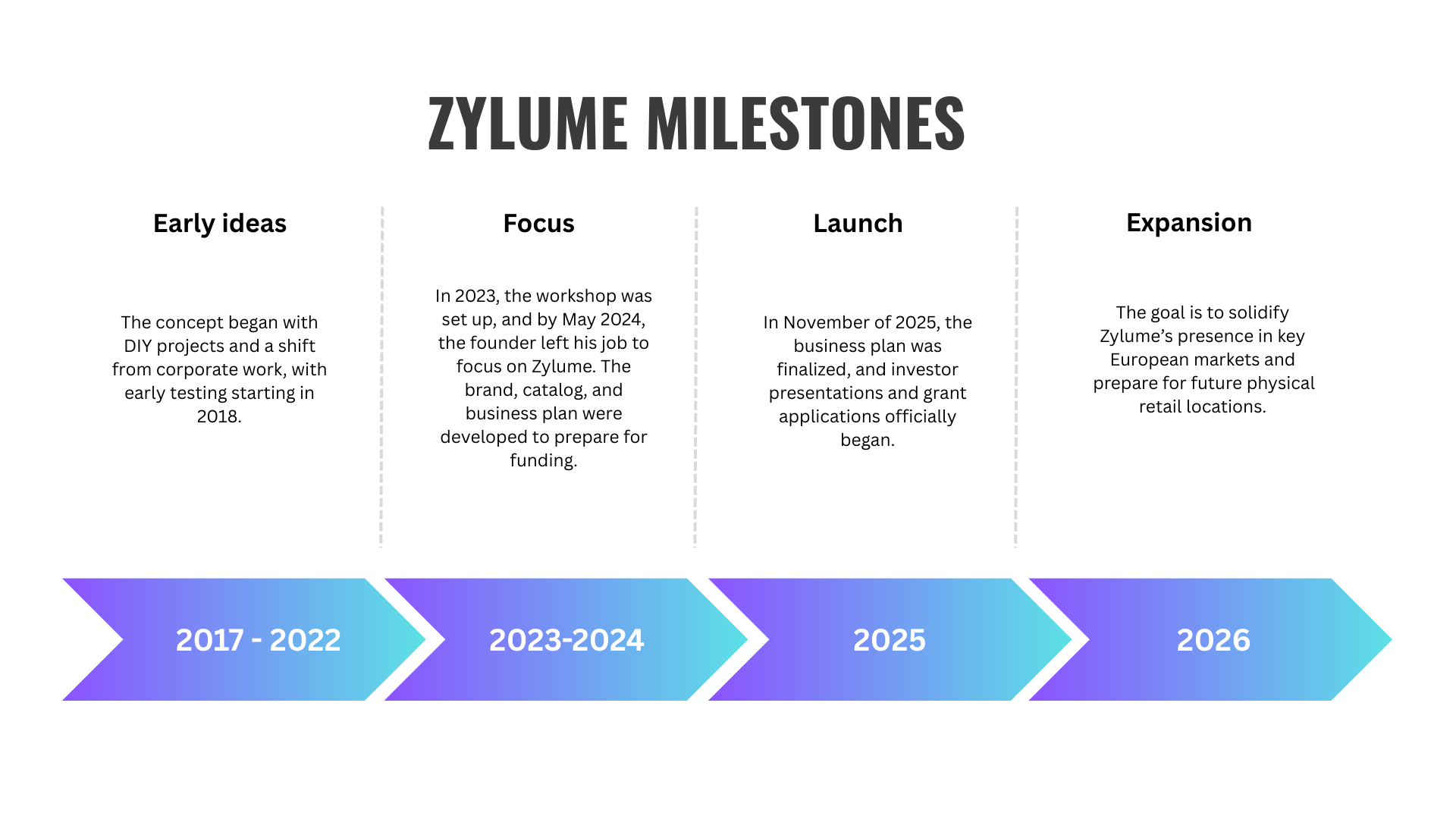

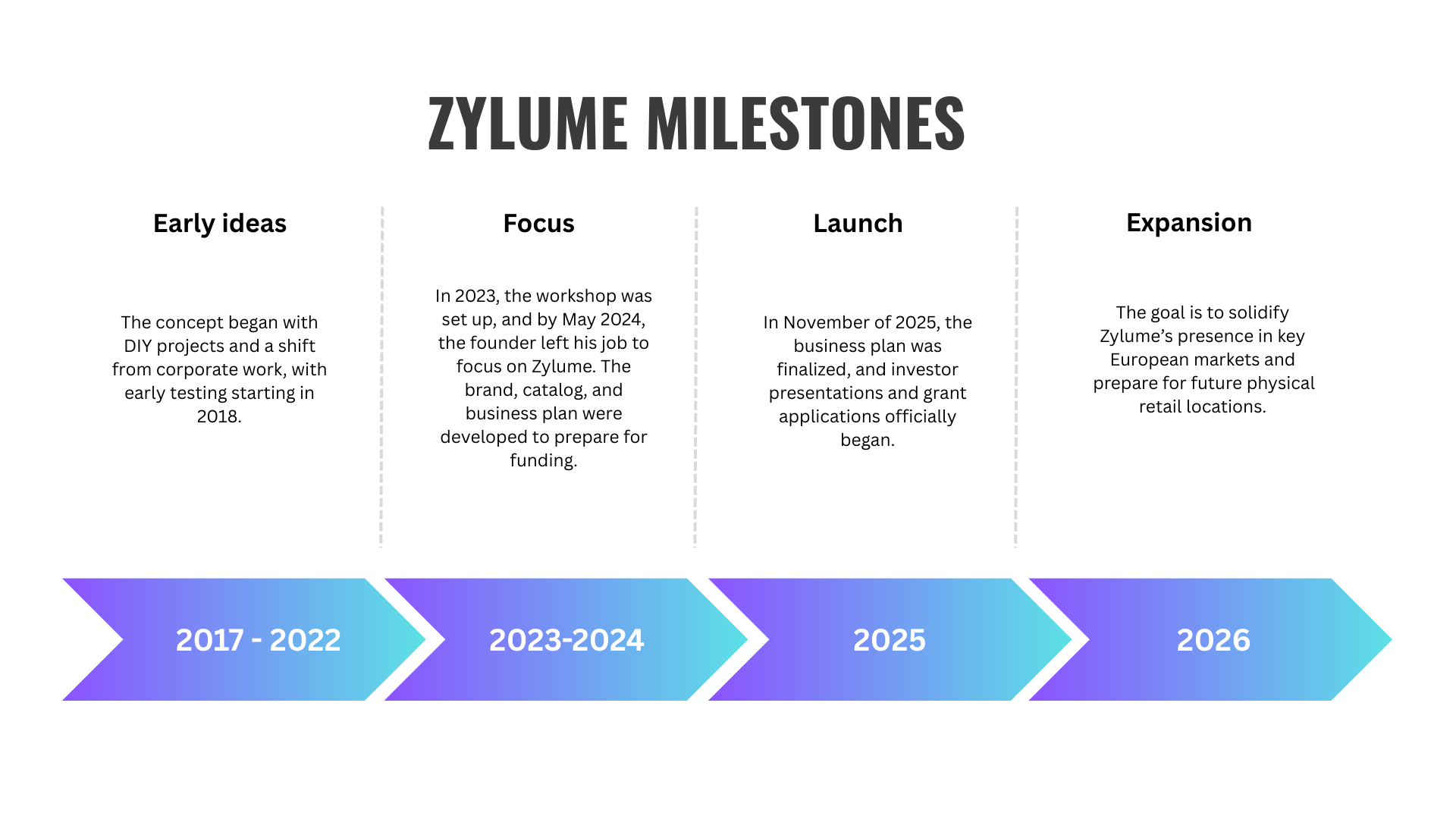

The first idea for Zylume began back in October 2017. After years of self-funded experimentation and development, the project evolved into a full-time business initiative in 2024, centered on eco-materials and local production.

11.1 Key Milestones

- 2017–2022: Early Ideation

Concept inspired by DIY projects and a desire for a creative career beyond the corporate world. Development progressed slowly due to full-time employment, but early prototypes and material testing began. - 2023–2024: Full-Time Commitment

Workshop space for prototyping set up in a newly acquired home.

Founder left corporate role in May 2024 to focus fully on Zylume.

Developed product recipes, brand identity, website, and catalog.

Created the full business plan and began planning funding and production. - November 2025

Business plan finalized and presented to investors and seed starters.

11.2 Growth Timeline

Pre-Launch Phase (Sept 2023 – November 2025)

- Improved product recipes, materials, and designs.

- Built brand, website, and seasonal product categories.

- Created product catalog and completed the full business plan.

- Prepared investor presentations and financing applications.

Manufacturing Setup (November 2025 - March 2026)

- Secure funding for launch operations.

- Set up the house workshop for manufacturing readiness.

- Begin production of the first product line.

- Prepare packaging and finalize e-commerce platform setup.

- Run a pre-launch marketing campaign to build brand awareness.

- Begin wholesale outreach to schools, event planners, and local councils (B2B).

Official Launch & Initial Manufacturing (March 2026)

- Launch at local events, eco fairs, and community markets.

- Open Zylume.sk for online sales.

- Start direct-to-consumer and social media-driven sales.

- Roll out digital and physical marketing campaigns.

- Gather early customer feedback to refine operations.

Full-Time Operation (January 2027)

- Transition to continuous, full-time production and order fulfillment.

- Launch the winter pre-season collection and maintain seasonal cycles.

- Optimize logistics, inventory, and customer service systems.

- Track performance and feedback to enhance product offerings.

- Prepare infrastructure and capacity for 2027 expansion.

11.3 Expansion Phase (January 2027 – 2028)

- Launch shipping to European countries Austria, Hungary, Czech Republic, Poland, and Germany.

- Begin opening physical retail locations in major Slovak cities.

11.4 Conclusion

Zylume has evolved from a simple goal into a well developed business with a clear, measurable growth path. By combining product innovation, operations, and scalable systems, Zylume is positioned for steady expansion throughout Slovakia and Central Europe by 2027.

Figure #5 — Zylume Growth Timeline Overview

Appendix A: Detailed breakdown of product categories

Below is a detailed breakdown of the product categories, including a general overview of the production process and the materials used for each type of item.

A.1 Vases, Lamps and Candle Holders

Zylume’s vases candle holders and lamps are lightweight, shatter-resistant and affordable. Once discarded, they naturally break down and return to the earth — allowing nature to absorb and reuse the minerals they contain.

Material Composition

Made from a blend of:

- plaster

- paper pulp

- flour

- Plaster

- Calcium hydroxide (lime)

- Volcanic ash

- Sand

- Sealed with linseed oil, beeswax and rosin (or damar resin) to create a water-resistant, natural finish

Production and Product Highlights

- Materials are mixed and poured into reusable molds made from epoxy or silicone.

- After curing and drying in the drying chamber, each piece is sanded in the sand blasting machine.

- The surface is coated with damar resin to give it a lacquered look and water resistance.

- The final product is stronger and more shatterproof than traditional ceramics.

- Available in seasonal shapes and natural color palettes.

- Suitable for table tops, shelves, or centerpiece styling.

Unit Production Cost and Pricing Strategy – Vases and candle holders

The average production cost for a standard vase measuring 180 mm × 70 mm × 10 mm with a we ight of 200 g is approximately €0.30 per piece. Our minimum target retail price is €3.00 per piece, providing a profit margin of around 94%. Pricing can be flexibly adjusted based on market response, seasonal demand, and perceived value and sizes of a vase.

Lamp Notes

Lamps are crafted using the same composite as Zylume’s vases and candle holders — a blend of calcium hydroxide, volcanic ash, and sand — making the lamp bodies durable, shatter-resistant, and fully biodegradable. Each lamp base is sealed with natural resins (linseed oil and damar) for water resistance and a smooth, polished finish.

The lampshades will be made from textiles such as cotton, jute, or linen.

All electrical components will be sourced externally but designed to be easily removable,

ensuring that the non-biodegradable parts can be separated and recycled efficiently at the

end of

the product’s life.

In the future, we plan to make long-lasting ceramic lamps instead of

biodegradable ones

A.2 Paintings, canvases

Cotton Canvas

The canvas itself is made from cotton cloth which is coated from one side with the mixture of paper pulp corn starch and glycerine, it will form a solid coating which will strenghten the canvas preventing it from cracking once the other side is coated with white gesso !

Production and Product Highlights

- Water-based eco ink (Arabic gum) or casein based inks .

- The artwork is screen-printed onto our in-house crafted cotton paper.

- The canvas will be made from raw cotton cloth, the backside of the canvas will be coated with our bioplastics blend (starch, glycerine, gelatine and paper pulp) and the front side will be coated with casein gesso ( casein + chalk )

- Water-based eco ink (Arabic gum) or oil-based letterpress ink (linseed oil).

- The artwork is screen-printed onto the canvas.

- Frames are produced in-house by cutting larger wood blocks into smaller components using a table saw, significantly reducing frame costs and optimizing material usage.

Sizes

Paintings will initially be available in three standard sizes, suitable for both wall décor and gifting:

- 40 × 30 cm – frame thickness 1 cm

- 50 × 40 cm – frame thickness 1.5 cm

- 60 × 45 cm – frame thickness 1.8 cm

Unit Production Cost and Pricing Strategy – Paintings

We produce our painting frames in-house by cutting large raw wood logs into smaller strips. Each log measures 300 cm × 10 cm × 10 cm (total volume: 30,000 cm³) and costs €20, resulting in a raw material cost of approximately €0.00067 per cm³.

For standard frames, we cut wooden strips sized 100 cm × 3 cm × 3 cm (volume: 900 cm³). The raw material cost to produce one such strip is approximately €0.60 with taxes included. This method keeps material costs low while ensuring quality control and consistency in frame production.

| Frame size | Thickness | Volume (cm³) | Frame cost (€) | Canvas cost (€) | Total material cost (€) |

|---|---|---|---|---|---|

| 40 × 30 cm | 1 cm | 140 | €0.09 | €0.18 | €0.27 |

| 50 × 40 cm | 1.5 cm | 405 | €0.27 | €0.29 | €0.56 |

| 60 × 45 cm | 1.8 cm | 680.4 | €0.46 | €0.40 | €0.86 |

A.3 Candles

Zylume’s candle collection offers a variety of shapes and scents for interiors. All candles are made from natural waxes beeswax, soy wax and carnauba wax, poured into molds or dipped.

Types of Candles

-

Dipped Candles

Created using the classic method with beeswax, soy wax, or coconut wax. -

Pillar Candles (Big Long Candles)

Made by pouring wax into reusable epoxy molds. -

Jar Candles

Wax is poured into jars made using the same natural mixture as our vases (e.g., plaster, perlite, lime, geopolymer).

Unit Production Cost and Pricing Strategy – Candles

We will source high-quality soy wax in bulk (20 kg packages) from certified Slovak suppliers, specifically from the online store mydlovysvet.sk. The price of 20 kg of soy wax is €133 (including tax).

as an example for cost comparison a pilar candle will weigh approximately 60 g, with dimensions of 20 cm in height and 2 cm in diameter. The retail price will be set at €1.00 per candle (excluding VAT), the production cost is around €0.4 per piece.

Though not our most profitable item, it plays a key role in attracting conscious buyers, reinforcing our brand, and supporting cross-selling of higher-margin products.

A.5 Table Banner Decor and Door Banners (Shapes and Design)

Zylume’s wood table décor and door banners are crafted from pressed paper pulp mixed with flour for rigidity, reinforced with wooden sheets on both sides, and finished with a screen-printed or stamped design.

Material and Production Composition

- Recycled paper pulp is pressed into firm sheets using a presser.

- Hardened sheets are cut into decorative shapes (e.g., circles, stars, leaves, abstract forms).

- The front and back sides are laminated with a thin wood sheet, cut in-house from larger logs (home made plywood ).

- Designs are applied using a screen-printing method.

- Edges and sides are sealed with a natural rosin coating to enhance durability while remaining fully compostable.

Design & Use

- Available in seasonal shapes and minimalistic or playful designs.

- Suitable for table decorations at home, weddings, events, shops, or festive displays.

- Lightweight and easy to set up or hang, if desired.

Unit Production Cost and Pricing Strategy – Table Banner Decor & Door Banners

Production is highly cost-effective. The primary material — paper pulp — is sourced free of charge from local shops through recycling initiatives. The main cost is casein orgum arabic ink used for screen printing, which amounts to approximately €0.10 per print.

As mentioned, the front and back of each object are laminated with thin wood sheets. Based on our calculations, a table décor design sized 15 cm × 12 cm costs approximately €0.10 in total for both sides.

Each piece of décor — either table or door hanging — will be sold for €5.00 (excluding taxes), allowing for a strong profit margin of around 96% while remaining affordable for our dear customers.

A.6 Wall Clocks & Frames

Zylume’s wall clocks and frames combine functionality with natural materials, offering a clean and sustainable alternative to conventional décor. Both product lines are designed to match our other collections, creating a cohesive look for any home.

Materials & Construction

Each piece is made from our house biodegradable composite blend of:

- Wood dust (for structure)

- Paper pulp (for structure)

- Perlite (for lightweight strength)

- Casein binder (for durability and cohesion)

Surfaces are hand-painted with casein paint and sealed with natural damar or linseed resin for a durable, water-resistant finish.

Design & Aesthetic

Both clocks and frames are available in minimal, modern, or seasonal styles — with some frames featuring playful, sculptural shapes inspired by maximalist, eclectic design or historical designs. They are lightweight, easy to mount, and designed as functional art pieces that express creativity, colour, and conscious living.

Clock Mechanism & Sustainability

The clock bodies are fully biodegradable, while the quartz mechanisms for the clocks are removable for recycling. Clear instructions will be included to support responsible e-waste handling.

Unit Production Cost and Pricing Strategy

The average composition of our composite is 60% wood dust or paper pulp, 30% perlite, and 10% casein binder. For a 300 g clock, the material cost is approximately €0.40 per unit (excluding taxes). A larger decorative frame weighing 500 g costs about €0.70 per unit.

Average retail prices:

- Wall clocks: €5.00

- Frames: €5.00

This results in an estimated profit margin of 85–94%, allowing us to keep prices affordable while maintaining strong profitability through low-cost, biodegradable materials and in-house manufacturing.

A.7 Banners

Zylume’s banners are crafted from cotton paper and jute cloth, designed for celebrations, seasonal decorations, or interior accents.

Materials & Production Methods

-

Cotton Paper

We create cotton paper from leftover cotton rags by turning them into pulp. This produces a stronger, more durable paper than regular types. The sheets are then cut into banner shapes and screen-printed with simple designs on the front. -

Jute Banners

Natural jute is cut into banner shapes, and the back side is sealed with a mix of cornstarch, glycerine and gelatine mixed with paper pulp to prevent fraying. The front is printed with minimal designs (letters or numbers only) using flexible casein paint or Arabic gum paint, preserving the raw, rustic jute look.

Unit Production Cost and Pricing Strategy – Banners

Our standard banner set includes 7 flags, with a total surface area of approximately 1,050 cm². Based on our material cost calculation (where 100 × 100 cm = €3.75), the production cost for one set of jute banners is approximately €0.39.

The average selling price for a jute banner set will be €5.00, with final pricing adjusted depending on size or customization.

For cotton banners, all materials — including cotton paper and additional natural ingredients — will be sourced for free from used cotton shirts and textiles. These cotton banners will be sold at an average price of €3.00 per flag (i.e., per set of 7 banners), offering strong margins while supporting upcycled and sustainable production.

A.8 Party Accessories

Zylume’s party accessories are designed to bring playful charm to seasonal celebrations, birthdays, holidays, and special events. These products are crafted using materials such as recycled paper, cotton paper, and rice paper ( for solubility).

Product Highlights & Materials

Piñatas

- Created using paper pulp sheets pressed into reusable molds, eliminating the need for labor-intensive hand layering.

- This method ensures structural consistency with lower production time.

- Once dried, the forms are decorated as needed for various themes using crepe paper (outsourced). Crepe paper will be glued to the pinata using a mixture of gelatine sugar and glycerine.

Paper Garlands & Curtains

- Made from Zylume’s own recycled paper, laser-cut into seasonal or decorative shapes for hanging.

- Lightweight, compostable, and ideal for temporary displays.

Biodegradable Confetti

- Produced from rice paper paste or from crushed leaves, designed to dissolve quickly upon contact with water.

- Ideal for outdoor celebrations with minimal environmental impact.

- Packaged in compostable paper tubes that open easily for throwing, with zero plastic waste.

Party Hats

- Molded from cotton paper pulp using reusable molds.

- Dried and shaped for use at birthdays, holidays (e.g., Halloween, Christmas), or themed events.

- Custom colours or textures can be added with eco-safe paints or finishes.

Outsourced Party Essentials

To complete our party range, we offer select items from trusted eco suppliers:

- Drinking straws

- Paper napkins

- Wooden cutlery

- Paper plates (In the future, we plan to develop our own eco plates.)

Zylume’s party line makes celebrating joyful, affordable, and eco-conscious — without the waste of traditional party supplies.

Unit Production Cost and Pricing Strategy – Party Accessories

Table #5 — Profit Margin of Selected Party Accessories

| Item | Cost (€) | Selling for (€) | Profit (€) | Profit Margin | Comment |

|---|---|---|---|---|---|

| Piñata | 0.1 | 7 | 6.9 | 98.57% | |

| Paper garland | 0.1 | 3 | 2.9 | 96.67% | |

| Party hats | 0.1 | 5 | 4.9 | 98.00% | |

| Confetti (one tube) | 0.1 | 1 | 0.9 | 90.00% |

Piñata Shipping Strategy

Due to the size and volume of our piñatas, standard parcel shipping through GLS or similar providers is not cost-effective for individual customer orders. A piñata measuring 30 × 50 × 10 cm can incur shipping fees exceeding €15 — which would significantly impact affordability and customer satisfaction.

To address this, we’ve adopted a dual-solution strategy:

-

Bulk Distribution for Shops & Events

We will prioritise selling piñatas in bulk quantities to local shops, event planners, and schools, where delivery can be arranged efficiently or in-person. This avoids excessive per-unit shipping costs while supporting seasonal retail demand. -

Development of a Collapsible Piñata Design

We are actively developing a collapsible piñata that can be shipped flat, reducing both size and volumetric weight. Customers will assemble it at home using simple included instructions and biodegradable ties. This format enables cost-effective domestic and EU shipping without compromising our eco mission.

This approach allows us to serve both local and remote customers effectively, while staying aligned with our goals of affordability, sustainability, and creative product design.

A.9 Home Kraft & Kids’ Activities

Zylume offers a line of eco-friendly creative kits for children and families, focused on fun, seasonal crafting with natural materials. These activities encourage creativity while teaching the value of sustainability and hands-on making.

Product Highlights

Paint-It-Yourself Shapes

- Shapes (like mini vases or figures) made using the same natural mixture as our full-sized vases.

- Each shape comes in a plain white or natural stone-like matte finish, ready to be painted.

- Customers can buy eco paint kits with powdered casein pigments and a small bottle of natural lacquer (damar resin) for sealing the final piece.

- Perfect for schools, workshops, or creative home time.

Papier-Mâché Animal Sculptures

- Lightweight animal figures created with natural paper pulp molds.

- Smooth surface for easy painting.

- Comes in seasonal or specific-themed kits.

- Fully biodegradable and safe for kids.

- Produced the same way as piñatas — using molds.

Wooden Stamp Sets

- Hand-cut wooden stamps in fun shapes like stars, animals, leaves, and letters.

- Can be used with casein ink or other natural paints.

- Encourages repeated play and creative reuse.

- Made from wood and laser engraved.

Unit Production Cost and Pricing Strategy – Home Kraft & Kids Activities

Paint-It-Yourself Shapes will cost roughly the same to make as vases or candle holders, resulting in a profit margin of over 90%. For papier-mâché animals, as with all paper-based items, the paper will be obtained from leftover cardboard from various businesses, keeping material costs at a minimum.

Table #6 — Profit Margin of Selected Home Kraft & Kids’ Items

| Item | Cost (€) | Selling for (€) | Profit (€) | Profit Margin | Comment |

|---|---|---|---|---|---|

| Paint-it-yourself vase | 0.1 | 7 | 6.9 | 98.57% | |

| Papier-Mâché Animal Sculptures | 0.1 | 3 | 2.9 | 96.67% | |

| Wooden Stamp Sets | 0.1 | 5 | 4.9 | 98.00% | |

| Confetti (one tube) | 0.1 | 1 | 0.9 | 90.00% |

A.12 In-Bulk Program for Schools

We offer special bulk packages for schools, giving them the opportunity to replace plastic items with our eco-friendly alternatives.

Painting and decorating these items gives students a fun and engaging experience, they get to colour what they see and hold in their hands.

By partnering with schools through long-term agreements or seasonal orders, we can build strong relationships while creating a steady and reliable source of income.

Products Offered in Bulk for Schools

- Pumpkins to Color – Perfect for autumn and Halloween activities.

- Templates to Color – 2D animal shapes on thick cardboard, ready for painting.

- Paper-Mâché Animals – 3D figures that students can paint and personalise.

- Coloring Masks – Paper masks in various styles and themes.

- Paper Helmets – Imaginative helmets kids can decorate any way they like.

Estimated Costs and Margins

By using low-cost, eco-conscious production methods — including the collection of discarded cardboard packaging from local shops — the production cost per item remains very low. This allows us to maintain profit margins of approximately 85–90% on school packages, ensuring that the program is both highly cost-efficient and financially sustainable while delivering strong social and environmental impact.

Appendix B: Detailed breakdown of Financial costs

Below is a detailed breakdown of all essential start-up and operational costs, including renovation of the manufacturing space, administrative and compliance fees, materials, equipment purchases, and projected labour expenses. This overview provides a clear financial structure for launching and sustaining Zylume’s production.

A.13 Place of Manufacturing

Facility Preparation Overview

Before manufacturing can begin, the production facility must be properly prepared. The designated location for manufacturing is a residential property at Hlavná 151, Kráľovský Chlmec, owned by the founder of Zylume Patrik Gaborcik. This property will be used as the primary site for crafting and producing Zylume’s biodegradable products.

To make the facility operational, several essential renovations and installations are required, including the construction of a drying room, three production rooms, and a bathroom for staff to use. The following figures outline the estimated costs and materials needed to prepare the space for manufacturing.

House Renovation Cost

The house has five rooms, a small kitchenette, and a bathroom. One room will be used as a drying room, three rooms for manufacturing, and one as the kitchenette. The total floor area is 96 m², and the total wall and ceiling area is 316 m².

- To keep the rooms warm and maintain a stable temperature in winter, the inner walls will be insulated with 10 cm thick rockwool panels fixed with plasterboards.

- The cost of insulating and plastering is about €4.07 per m². For the entire wall and ceiling area, the total cost will be approximately €1,285.80 (316 m² × €4.07).

- The floors need to be levelled with concrete. The total floor area is 96 m², and 10 cm thick concrete costs about €27.01 per m², resulting in a total of €2,593.34.

- After the concrete sets, it will be sealed with an epoxy coating. Around 40 kg of epoxy will be needed, costing approximately €691.60.

- For the drying room, the walls will be insulated with 10 cm thick polystyrene from the inside to keep the temperature steady and prevent heat loss. The total polystyrene cost for this insulation is approximately €520.00.

Total estimated renovation material cost: €5,090.75

Labour Cost Estimation Methodology

The projected labour cost for renovating the manufacturing facility is based on average construction and renovation labour rates in Slovakia for 2024. This estimate covers wall insulation and plastering, concrete floor levelling, epoxy floor sealing, and general site preparation work.

Breakdown of Estimated Labour Costs:

- Wall insulation and plastering: €15.60 per m² × 316 m² = €4,929.60

- Concrete floor levelling: €19.50 per m² × 96 m² = €1,872.00

- Epoxy floor sealing: €10.40 per m² × 96 m² = €998.40

- General preparatory work and setup: €2,600.00

Total estimated labour cost: €10,400.00

Overall estimated renovation budget (materials + labour): €15,490.75

Labour costs are calculated based on average construction labour rates in Slovakia, referenced from

Eurostat data.

Source:

Eurostat – Labour Cost Index: Construction, Slovakia via

Trading Economics

.

It is important to note that actual costs may vary depending on specific project requirements, regional labour market conditions, and the selection of contractors. Engaging local contractors or independent workers in the Kráľovský Chlmec region may offer opportunities for cost optimisation through negotiated rates or in-kind contributions.

Note: The estimated labour cost of €15,490.75 reflects standard market rates for renovation work in Slovakia. This cost may be reduced through cooperation with local contractors or independent workers, particularly by sourcing labour within the Kráľovský Chlmec region. Leveraging local relationships may allow for negotiated pricing or partial in-kind contributions, helping to lower overall renovation expenses without compromising work quality.

Table #8 of the prices of materials used for the house renovation :

| Item | Qty / Basis | Unit cost | Subtotal (€) |

|---|---|---|---|

| Wall & ceiling insulation + plasterboard | 316 m² | €4.07 / m² | €1,285.80 |

| Concrete floor (10 cm) | 96 m² | €27.01 / m² | €2,593.34 |

| Epoxy coating (≈40 kg) | — | — | €691.60 |

| Polystyrene (drying room) | — | — | €520.00 |

| Materials subtotal | €5,090.75 | ||

Table #9 Detailed Labour Costs for Facility Preparation and Installation Work :

| Work item | Basis | Rate | Subtotal (€) |

|---|---|---|---|

| Wall insulation & plastering | 316 m² | €15.60 / m² | €4,929.60 |

| Concrete floor levelling | 96 m² | €19.50 / m² | €1,872.00 |

| Epoxy floor sealing | 96 m² | €10.40 / m² | €998.40 |

| General preparatory work | — | — | €2,600.00 |

| Labour subtotal | €10,400.00 | ||

Table #10 Summary of Total Materials and Labour Costs (Scenario B) :

| Scenario | Materials (€) | Labour (€) | Total (€) |

|---|---|---|---|

| B — Realistic renovation scenario | €5,090.75 | €10,400.00 | €15,490.75 |

A.14 Materials Being Used for Manufacturing

We experimented with different natural materials to find the best combinations for our products. All materials are locally sourced, ensuring quick availability without long waiting times.

Main Natural Materials

Used as binding materials, glues or paints

- Waxes: Soy, palm, beeswax, and carnauba wax – used in candles and coatings.

- Linseed oil: A natural water-repellent used for wood finishing.

- Natural pigments: Plant and mineral colourants for paints and décor finishes.

- Arabic gum: A natural binder used in paper, paint, and coatings.

- Glycerine: Adds flexibility to paper, glue, and soap products.

- Rosins (including damar resin): Used as eco varnish for sealing and shine.

- Micellar casein: A biodegradable binder for paints and papier-mâché.

- Shellac: A natural resin that gives a smooth, glossy finish.

Base Ingredients

These materials give our products structure, strength, and volume.

- Volcanic ash: Lightweight and fire-resistant material.

- Lime: Adds strength and an antibacterial surface finish.

- Corn starch: Natural thickener and binder for pastes and coatings.

- Chalk powder: Filler that provides a smooth, matte texture.

- Wood dust: Filler used in natural composite materials.

- Perlite: Lightweight filler that helps with insulation.

- Natural clay: Adds structure and natural texture.

- Wheat paste: Traditional biodegradable binder for papier-mâché and packaging.

- Plaster: Used for shaping vases, candle holders, and decorative items.

- Metakaolin: A ceramic additive that strengthens vase mixtures.

- Wood logs (9.8 × 9.8 cm): Used for bases, supports, and carvings.

- Jute: Natural fibre used for wrapping, weaving, and structure.